How processing waste fibers turned into the manufacturing of smart textiles for cable protection, composites and condensation solutions

1959

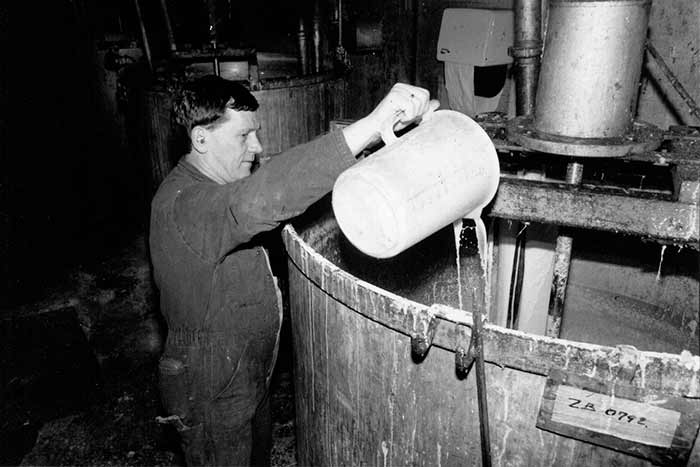

Hollantor B.V. was founded in Veenendaal, the Netherlands, with the aim to process waste fibers of the Veenendaal textile industry into nonwovens. These nonwovens were used for interlinings in clothing and as underlay for carpets. The product range was soon expanded by also using virgin fibers from both synthetic and natural base, such as polyester, nylon, cotton, wool and rayon. A nonwoven company was born.

1971

The company is renamed to Firet B.V. and operated 13 chembond and 5 needle felt nonwoven lines to produce nonwovens for a wide scala of applications.

1974 – 1975

A technology was invented to combine nonwoven with subsequent foaming technology, yielding a futuristic technical textile for that time. This textile provided exceptional properties for use as laminate bulker in glass fiber reinforced plastics, the first product of that kind in the market. The product was called Firet Coremat® XX, later renamed to Coremat® Xi, a product that is still the bench mark in the composites industry. In these years also the first products were developed for the cable industry for which a carbon impregnation line was installed to make nonwovens semi-conductive.

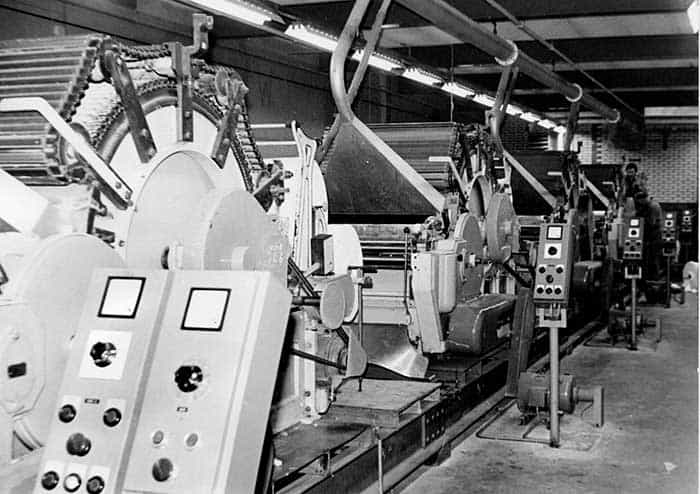

1980 – 1984

For the cable market tape slitting and winding machines were installed, which was the start of a complete slitting and spooling department for cable tapes that is still fully operational at Lantor. The foaming technology advanced by the invention of foam printing technology. This technology provided a new product for the composite market, Firet Coremat® XM, still the best core material in the market for hand layup processes.

1984 – 1985

The swelling tape was invented; a unique laminate of nonwoven and superabsorbent polymer that protects the cable for damage by water penetration. Application of such water blocking tapes soon became the standard in the cable industry.

1987 – 1995

Firet was renamed to Lantor. Later, the Firet brand was sold together with the interlining business. The Coremat® brand remained with Lantor. Lamination lines were installed to produce tapes for the growing cable market. With the growing knowledge on textile foams, a special nonwoven was developed with unique properties to prevent condensation issues in roofing applications: the brand Condenstop® was born. Lantor was turned into a highly specialized technical textile company more than a nonwoven company only.

2000 – 2002

As a response to the development of the infustion technology, Lantor developed the unique and patented Soric® nonwoven foam printing technology, that provided in a pressure resistant core material for composites, first with honeycomb patterns and later also with a special dotted pattern for applications with aesthetic requirements. For Condenstop® a hotmelt line was installed to make the product self adherent.

2016 – present

New brands were added to the family of core materials: Skincore® a multilayer product and the patented Teccore® brand, a flexible foam core for composite processes that require high pressures and temperatures. To optimize its activities Lantor decided to focus on its current 3 product groups: Lantor Cable, Composites and Condenstop.